chii chinonzi rubber o-ring uye rudzi rwerubha runoshandiswa muma-o-rings?

chii chinonzi rubber o-ring uye rudzi rwerubha runoshandiswa muma-o-rings?

Chekutanga -please tarisa oring size AS568

| AS568 SIZE | Nominal ID | Nominal C/S | Chiyero ID in inches | ± ID | Zviyero CS mumasendimita | ± CS | Chiyero ID mu mm | ± ID | Zviyero CS mu mm | ± C/S | ||||||||||

| -1 | 1/32 | 1/32 | 0.029 | 0.004 | 0.040 | 0.003 | 0.74 | 0.10 | 1.02 | 0.08 | ||||||||||

| -2 | 3/64 | 3/64 | 0.042 | 0.004 | 0.050 | 0.003 | 1.07 | 0.10 | 1.27 | 0.08 | ||||||||||

| -3 | 1/16 | 1/16 | 0.056 | 0.004 | 0.060 | 0.003 | 1.42 | 0.10 | 1.52 | 0.08 | ||||||||||

| -4 | 5/64 | 1/16 | 0.070 | 0.005 | 0.070 | 0.003 | 1.78 | 0.13 | 1.78 | 0.08 | ||||||||||

| -5 | 3/32 | 1/16 | 0.101 | 0.005 | 0.070 | 0.003 | 2.57 | 0.13 | 1.78 | 0.08 | ||||||||||

| -6 | 1/8 | 1/16 | 0.114 | 0.005 | 0.070 | 0.003 | 2.90 | 0.13 | 1.78 | 0.08 | ||||||||||

| -7 | 5/32 | 1/16 | 0.145 | 0.005 | 0.070 | 0.003 | 3.68 | 0.13 | 1.78 | 0.08 | ||||||||||

| -8 | 3/16 | 1/16 | 0.176 | 0.005 | 0.070 | 0.003 | 4.47 | 0.13 | 1.78 | 0.08 | ||||||||||

| -9 | 7/32 | 1/16 | 0.208 | 0.005 | 0.070 | 0.003 | 5.28 | 0.13 | 1.78 | 0.08 | ||||||||||

| -10 | 1/4 | 1/16 | 0.239 | 0.005 | 0.070 | 0.003 | 6.07 | 0.13 | 1.78 | 0.08 | ||||||||||

| -11 | 5/16 | 1/16 | 0.301 | 0.005 | 0.070 | 0.003 | 7.65 | 0.13 | 1.78 | 0.08 | ||||||||||

| -12 | 3/8 | 1/16 | 0.364 | 0.005 | 0.070 | 0.003 | 9.25 | 0.13 | 1.78 | 0.08 | ||||||||||

| -13 | 7/16 | 1/16 | 0.426 | 0.005 | 0.070 | 0.003 | 10.82 | 0.13 | 1.78 | 0.08 | ||||||||||

| -14 | 1/2 | 1/16 | 0.489 | 0.005 | 0.070 | 0.003 | 12.42 | 0.13 | 1.78 | 0.08 | ||||||||||

| -15 | 9/16 | 1/16 | 0.551 | 0.007 | 0.070 | 0.003 | 14.00 | 0.18 | 1.78 | 0.08 | ||||||||||

| -16 | 5/8 | 1/16 | 0.614 | 0.009 | 0.070 | 0.003 | 15.60 | 0.23 | 1.78 | 0.08 | ||||||||||

| -17 | 11/16 | 1/16 | 0.676 | 0.009 | 0.070 | 0.003 | 17.17 | 0.23 | 1.78 | 0.08 | ||||||||||

| -18 | 3/4 | 1/16 | 0.739 | 0.009 | 0.070 | 0.003 | 18.77 | 0.23 | 1.78 | 0.08 | ||||||||||

| -19 | 13/16 | 1/16 | 0.801 | 0.009 | 0.070 | 0.003 | 20.35 | 0.23 | 1.78 | 0.08 | ||||||||||

| -20 | 7/8 | 1/16 | 0.864 | 0.009 | 0.070 | 0.003 | 21.95 | 0.23 | 1.78 | 0.08 | ||||||||||

| -21 | 15/16 | 1/16 | 0.926 | 0.009 | 0.070 | 0.003 | 23.52 | 0.23 | 1.78 | 0.08 | ||||||||||

| -22 | 1 | 1/16 | 0.989 | 0.010 | 0.070 | 0.003 | 25.12 | 0.25 | 1.78 | 0.08 | ||||||||||

| -23 | 1 1/16 | 1/16 | 1.051 | 0.010 | 0.070 | 0.003 | 26.70 | 0.25 | 1.78 | 0.08 | ||||||||||

| -24 | 1 1/8 | 1/16 | 1.114 | 0.010 | 0.070 | 0.003 | 28.30 | 0.25 | 1.78 | 0.08 | ||||||||||

| -25 | 1 3/16 | 1/16 | 1.176 | 0.011 | 0.070 | 0.003 | 29.87 | 0.28 | 1.78 | 0.08 | ||||||||||

| -26 | 1 1/4 | 1/16 | 1.239 | 0.011 | 0.070 | 0.003 | 31.47 | 0.28 | 1.78 | 0.08 | ||||||||||

| -27 | 1 5/16 | 1/16 | 1.301 | 0.011 | 0.070 | 0.003 | 33.05 | 0.28 | 1.78 | 0.08 | ||||||||||

| -28 | 1 3/8 | 1/16 | 1.364 | 0.013 | 0.070 | 0.003 | 34.65 | 0.33 | 1.78 | 0.08 | ||||||||||

| -29 | 1 1/2 | 1/16 | 1.489 | 0.013 | 0.070 | 0.003 | 37.82 | 0.33 | 1.78 | 0.08 | ||||||||||

| -30 | 1 5/8 | 1/16 | 1.614 | 0.013 | 0.070 | 0.003 | 41.00 | 0.33 | 1.78 | 0.08 | ||||||||||

| -31 | 1 3/4 | 1/16 | 1.739 | 0.015 | 0.070 | 0.003 | 44.17 | 0.38 | 1.78 | 0.08 | ||||||||||

| -32 | 1 7/8 | 1/16 | 1.864 | 0.015 | 0.070 | 0.003 | 47.35 | 0.38 | 1.78 | 0.08 | ||||||||||

| -33 | 2 | 1/16 | 1.989 | 0.018 | 0.070 | 0.003 | 50.52 | 0.46 | 1.78 | 0.08 | ||||||||||

| -34 | 2 1/8 | 1/16 | 2.114 | 0.018 | 0.070 | 0.003 | 53.70 | 0.46 | 1.78 | 0.08 | ||||||||||

| -35 | 2 1/4 | 1/16 | 2.239 | 0.018 | 0.070 | 0.003 | 56.87 | 0.46 | 1.78 | 0.08 | ||||||||||

| -36 | 2 3/8 | 1/16 | 2.364 | 0.018 | 0.070 | 0.003 | 60.05 | 0.46 | 1.78 | 0.08 | ||||||||||

| -37 | 2 1/2 | 1/16 | 2.489 | 0.018 | 0.070 | 0.003 | 63.22 | 0.46 | 1.78 | 0.08 | ||||||||||

| -38 | 2 5/8 | 1/16 | 2.614 | 0.020 | 0.070 | 0.003 | 66.40 | 0.51 | 1.78 | 0.08 | ||||||||||

| -39 | 2 3/4 | 1/16 | 2.739 | 0.020 | 0.070 | 0.003 | 69.57 | 0.51 | 1.78 | 0.08 | ||||||||||

| -40 | 2 7/8 | 1/16 | 2.864 | 0.020 | 0.070 | 0.003 | 72.75 | 0.51 | 1.78 | 0.08 | ||||||||||

| -41 | 3 | 1/16 | 2.989 | 0.024 | 0.070 | 0.003 | 75.92 | 0.61 | 1.78 | 0.08 | ||||||||||

| -42 | 3 1/4 | 1/16 | 3.239 | 0.024 | 0.070 | 0.003 | 82.27 | 0.61 | 1.78 | 0.08 | ||||||||||

| -43 | 3 1/2 | 1/16 | 3.489 | 0.024 | 0.070 | 0.003 | 88.62 | 0.61 | 1.78 | 0.08 | ||||||||||

| -44 | 3 3/4 | 1/16 | 3.739 | 0.027 | 0.070 | 0.003 | 94.97 | 0.69 | 1.78 | 0.08 | ||||||||||

| -45 | 4 | 1/16 | 3.989 | 0.027 | 0.070 | 0.003 | 101.32 | 0.69 | 1.78 | 0.08 | ||||||||||

| -46 | 4 1/4 | 1/16 | 4.239 | 0.030 | 0.070 | 0.003 | 107.67 | 0.76 | 1.78 | 0.08 | ||||||||||

| -47 | 4 1/2 | 1/16 | 4.489 | 0.030 | 0.070 | 0.003 | 114.02 | 0.76 | 1.78 | 0.08 | ||||||||||

| -48 | 4 3/4 | 1/16 | 4.739 | 0.030 | 0.070 | 0.003 | 120.37 | 0.76 | 1.78 | 0.08 | ||||||||||

| -49 | 5 | 1/16 | 4.989 | 0.037 | 0.070 | 0.003 | 126.72 | 0.94 | 1.78 | 0.08 | ||||||||||

| -50 | 5 1/4 | 1/16 | 5.239 | 0.037 | 0.070 | 0.003 | 133.07 | 0.94 | 1.78 | 0.08 | ||||||||||

| -102 | 1/16 | 3/32 | 0.049 | 0.005 | 0.103 | 0.003 | 1.24 | 0.13 | 2.62 | 0.08 | ||||||||||

| -103 | 3/32 | 3/32 | 0.081 | 0.005 | 0.103 | 0.003 | 2.06 | 0.13 | 2.62 | 0.08 | ||||||||||

| -104 | 1/8 | 3/32 | 0.112 | 0.005 | 0.103 | 0.003 | 2.84 | 0.13 | 2.62 | 0.08 | ||||||||||

| -105 | 5/32 | 3/32 | 0.143 | 0.005 | 0.103 | 0.003 | 3.63 | 0.13 | 2.62 | 0.08 | ||||||||||

| -106 | 3/16 | 3/32 | 0.174 | 0.005 | 0.103 | 0.003 | 4.42 | 0.13 | 2.62 | 0.08 | ||||||||||

| -107 | 7/32 | 3/32 | 0.206 | 0.005 | 0.103 | 0.003 | 5.23 | 0.13 | 2.62 | 0.08 | ||||||||||

| -108 | 1/4 | 3/32 | 0.237 | 0.005 | 0.103 | 0.003 | 6.02 | 0.13 | 2.62 | 0.08 | ||||||||||

| -109 | 5/16 | 3/32 | 0.299 | 0.005 | 0.103 | 0.003 | 7.59 | 0.13 | 2.62 | 0.08 | ||||||||||

| -110 | 3/8 | 3/32 | 0.362 | 0.005 | 0.103 | 0.003 | 9.19 | 0.13 | 2.62 | 0.08 | ||||||||||

| -111 | 7/16 | 3/32 | 0.424 | 0.005 | 0.103 | 0.003 | 10.77 | 0.13 | 2.62 | 0.08 | ||||||||||

| -112 | 1/2 | 3/32 | 0.487 | 0.005 | 0.103 | 0.003 | 12.37 | 0.13 | 2.62 | 0.08 | ||||||||||

| -113 | 9/16 | 3/32 | 0.549 | 0.007 | 0.103 | 0.003 | 13.94 | 0.18 | 2.62 | 0.08 | ||||||||||

| -114 | 5/8 | 3/32 | 0.612 | 0.009 | 0.103 | 0.003 | 15.54 | 0.23 | 2.62 | 0.08 | ||||||||||

| -115 | 11/16 | 3/32 | 0.674 | 0.009 | 0.103 | 0.003 | 17.12 | 0.23 | 2.62 | 0.08 | ||||||||||

| -116 | 3/4 | 3/32 | 0.737 | 0.009 | 0.103 | 0.003 | 18.72 | 0.23 | 2.62 | 0.08 | ||||||||||

| -117 | 13/16 | 3/32 | 0.799 | 0.010 | 0.103 | 0.003 | 20.29 | 0.25 | 2.62 | 0.08 | ||||||||||

| -118 | 7/8 | 3/32 | 0.862 | 0.010 | 0.103 | 0.003 | 21.89 | 0.25 | 2.62 | 0.08 | ||||||||||

| -119 | 15/16 | 3/32 | 0.924 | 0.010 | 0.103 | 0.003 | 23.47 | 0.25 | 2.62 | 0.08 | ||||||||||

| -120 | 1 | 3/32 | 0.987 | 0.010 | 0.103 | 0.003 | 25.07 | 0.25 | 2.62 | 0.08 | ||||||||||

| -121 | 1 1/16 | 3/32 | 1.049 | 0.010 | 0.103 | 0.003 | 26.64 | 0.25 | 2.62 | 0.08 | ||||||||||

| -122 | 1 1/8 | 3/32 | 1.112 | 0.010 | 0.103 | 0.003 | 28.24 | 0.25 | 2.62 | 0.08 | ||||||||||

| -123 | 1 3/16 | 3/32 | 1.174 | 0.012 | 0.103 | 0.003 | 29.82 | 0.30 | 2.62 | 0.08 | ||||||||||

| -124 | 1 1/4 | 3/32 | 1.237 | 0.012 | 0.103 | 0.003 | 31.42 | 0.30 | 2.62 | 0.08 | ||||||||||

| -125 | 1 5/16 | 3/32 | 1.299 | 0.012 | 0.103 | 0.003 | 32.99 | 0.30 | 2.62 | 0.08 | ||||||||||

| -126 | 1 3/8 | 3/32 | 1.362 | 0.012 | 0.103 | 0.003 | 34.59 | 0.30 | 2.62 | 0.08 | ||||||||||

| -127 | 1 7/16 | 3/32 | 1.424 | 0.012 | 0.103 | 0.003 | 36.17 | 0.30 | 2.62 | 0.08 | ||||||||||

| -128 | 1 1/2 | 3/32 | 1.487 | 0.012 | 0.103 | 0.003 | 37.77 | 0.30 | 2.62 | 0.08 | ||||||||||

| -129 | 1 9/16 | 3/32 | 1.549 | 0.015 | 0.103 | 0.003 | 39.34 | 0.38 | 2.62 | 0.08 | ||||||||||

| -130 | 1 5/8 | 3/32 | 1.612 | 0.015 | 0.103 | 0.003 | 40.94 | 0.38 | 2.62 | 0.08 | ||||||||||

| -131 | 1 11/16 | 3/32 | 1.674 | 0.015 | 0.103 | 0.003 | 42.52 | 0.38 | 2.62 | 0.08 | ||||||||||

| -132 | 1 3/4 | 3/32 | 1.737 | 0.015 | 0.103 | 0.003 | 44.12 | 0.38 | 2.62 | 0.08 | ||||||||||

| -133 | 1 13/16 | 3/32 | 1.799 | 0.015 | 0.103 | 0.003 | 45.69 | 0.38 | 2.62 | 0.08 | ||||||||||

| -134 | 1 7/8 | 3/32 | 1.862 | 0.015 | 0.103 | 0.003 | 47.29 | 0.38 | 2.62 | 0.08 | ||||||||||

| -135 | 1 15/16 | 3/32 | 1.925 | 0.017 | 0.103 | 0.003 | 48.90 | 0.43 | 2.62 | 0.08 | ||||||||||

| -136 | 2 | 3/32 | 1.987 | 0.017 | 0.103 | 0.003 | 50.47 | 0.43 | 2.62 | 0.08 | ||||||||||

| -137 | 2 1/16 | 3/32 | 2.050 | 0.017 | 0.103 | 0.003 | 52.07 | 0.43 | 2.62 | 0.08 | ||||||||||

| -138 | 2 1/8 | 3/32 | 2.112 | 0.017 | 0.103 | 0.003 | 53.64 | 0.43 | 2.62 | 0.08 | ||||||||||

| -139 | 2 3/16 | 3/32 | 2.175 | 0.017 | 0.103 | 0.003 | 55.25 | 0.43 | 2.62 | 0.08 | ||||||||||

| -140 | 2 1/4 | 3/32 | 2.237 | 0.017 | 0.103 | 0.003 | 56.82 | 0.43 | 2.62 | 0.08 | ||||||||||

| -141 | 2 5/16 | 3/32 | 2.300 | 0.020 | 0.103 | 0.003 | 58.42 | 0.51 | 2.62 | 0.08 | ||||||||||

| -142 | 2 3/8 | 3/32 | 2.362 | 0.020 | 0.103 | 0.003 | 59.99 | 0.51 | 2.62 | 0.08 | ||||||||||

| -143 | 2 7/16 | 3/32 | 2.425 | 0.020 | 0.103 | 0.003 | 61.60 | 0.51 | 2.62 | 0.08 | ||||||||||

| -144 | 2 1/2 | 3/32 | 2.487 | 0.020 | 0.103 | 0.003 | 63.17 | 0.51 | 2.62 | 0.08 | ||||||||||

| -145 | 2 9/16 | 3/32 | 2.550 | 0.020 | 0.103 | 0.003 | 64.77 | 0.51 | 2.62 | 0.08 | ||||||||||

| -146 | 2 5/8 | 3/32 | 2.612 | 0.020 | 0.103 | 0.003 | 66.34 | 0.51 | 2.62 | 0.08 | ||||||||||

| -147 | 2 11/16 | 3/32 | 2.675 | 0.022 | 0.103 | 0.003 | 67.95 | 0.56 | 2.62 | 0.08 | ||||||||||

| -148 | 2 3/4 | 3/32 | 2.737 | 0.022 | 0.103 | 0.003 | 69.52 | 0.56 | 2.62 | 0.08 | ||||||||||

| -149 | 2 13/16 | 3/32 | 2.800 | 0.022 | 0.103 | 0.003 | 71.12 | 0.56 | 2.62 | 0.08 | ||||||||||

| -150 | 2 7/8 | 3/32 | 2.862 | 0.022 | 0.103 | 0.003 | 72.69 | 0.56 | 2.62 | 0.08 | ||||||||||

| -151 | 3 | 3/32 | 2.987 | 0.024 | 0.103 | 0.003 | 75.87 | 0.61 | 2.62 | 0.08 | ||||||||||

| -152 | 3 1/4 | 3/32 | 3.237 | 0.024 | 0.103 | 0.003 | 82.22 | 0.61 | 2.62 | 0.08 | ||||||||||

| -153 | 3 1/2 | 3/32 | 3.487 | 0.024 | 0.103 | 0.003 | 88.57 | 0.61 | 2.62 | 0.08 | ||||||||||

| -154 | 3 3/4 | 3/32 | 3.737 | 0.028 | 0.103 | 0.003 | 94.92 | 0.71 | 2.62 | 0.08 | ||||||||||

| -155 | 4 | 3/32 | 3.987 | 0.028 | 0.103 | 0.003 | 101.27 | 0.71 | 2.62 | 0.08 | ||||||||||

| -156 | 4 1/4 | 3/32 | 4.237 | 0.030 | 0.103 | 0.003 | 107.62 | 0.76 | 2.62 | 0.08 | ||||||||||

| -157 | 4 1/2 | 3/32 | 4.487 | 0.030 | 0.103 | 0.003 | 113.97 | 0.76 | 2.62 | 0.08 | ||||||||||

| -158 | 4 3/4 | 3/32 | 4.737 | 0.030 | 0.103 | 0.003 | 120.32 | 0.76 | 2.62 | 0.08 | ||||||||||

| -159 | 5 | 3/32 | 4.987 | 0.035 | 0.103 | 0.003 | 126.67 | 0.89 | 2.62 | 0.08 | ||||||||||

| -160 | 5 1/4 | 3/32 | 5.237 | 0.035 | 0.103 | 0.003 | 133.02 | 0.89 | 2.62 | 0.08 | ||||||||||

| -161 | 5 1/2 | 3/32 | 5.487 | 0.035 | 0.103 | 0.003 | 139.37 | 0.89 | 2.62 | 0.08 | ||||||||||

| -162 | 5 3/4 | 3/32 | 5.737 | 0.035 | 0.103 | 0.003 | 145.72 | 0.89 | 2.62 | 0.08 | ||||||||||

| -163 | 6 | 3/32 | 5.987 | 0.035 | 0.103 | 0.003 | 152.07 | 0.89 | 2.62 | 0.08 | ||||||||||

| -164 | 6 1/4 | 3/32 | 6.237 | 0.040 | 0.103 | 0.003 | 158.42 | 1.02 | 2.62 | 0.08 | ||||||||||

| -165 | 6 1/2 | 3/32 | 6.487 | 0.040 | 0.103 | 0.003 | 164.77 | 1.02 | 2.62 | 0.08 | ||||||||||

| -166 | 6 3/4 | 3/32 | 6.737 | 0.040 | 0.103 | 0.003 | 171.12 | 1.02 | 2.62 | 0.08 | ||||||||||

| -167 | 7 | 3/32 | 6.987 | 0.040 | 0.103 | 0.003 | 177.47 | 1.02 | 2.62 | 0.08 | ||||||||||

| -168 | 7 1/4 | 3/32 | 7.237 | 0.045 | 0.103 | 0.003 | 183.82 | 1.14 | 2.62 | 0.08 | ||||||||||

| -169 | 7 1/2 | 3/32 | 7.487 | 0.045 | 0.103 | 0.003 | 190.17 | 1.14 | 2.62 | 0.08 | ||||||||||

| -170 | 7 3/4 | 3/32 | 7.737 | 0.045 | 0.103 | 0.003 | 196.52 | 1.14 | 2.62 | 0.08 | ||||||||||

| -171 | 8 | 3/32 | 7.987 | 0.045 | 0.103 | 0.003 | 202.87 | 1.14 | 2.62 | 0.08 | ||||||||||

| -172 | 8 1/4 | 3/32 | 8.237 | 0.050 | 0.103 | 0.003 | 209.22 | 1.27 | 2.62 | 0.08 | ||||||||||

| -173 | 8 1/2 | 3/32 | 8.487 | 0.050 | 0.103 | 0.003 | 215.57 | 1.27 | 2.62 | 0.08 | ||||||||||

| -174 | 8 3/4 | 3/32 | 8.737 | 0.050 | 0.103 | 0.003 | 221.92 | 1.27 | 2.62 | 0.08 | ||||||||||

| -175 | 9 | 3/32 | 8.987 | 0.050 | 0.103 | 0.003 | 228.27 | 1.27 | 2.62 | 0.08 | ||||||||||

| -176 | 9 1/4 | 3/32 | 9.237 | 0.055 | 0.103 | 0.003 | 234.62 | 1.40 | 2.62 | 0.08 | ||||||||||

| -177 | 9 1/2 | 3/32 | 9.487 | 0.055 | 0.103 | 0.003 | 240.97 | 1.40 | 2.62 | 0.08 | ||||||||||

| -178 | 9 3/4 | 3/32 | 9.737 | 0.055 | 0.103 | 0.003 | 247.32 | 1.40 | 2.62 | 0.08 | ||||||||||

| -201 | 3/16 | 1/8 | 0.171 | 0.005 | 0.139 | 0.004 | 4.34 | 0.13 | 3.53 | 0.10 | ||||||||||

| -202 | 1/4 | 1/8 | 0.234 | 0.005 | 0.139 | 0.004 | 5.94 | 0.13 | 3.53 | 0.10 | ||||||||||

| -203 | 5/16 | 1/8 | 0.296 | 0.005 | 0.139 | 0.004 | 7.52 | 0.13 | 3.53 | 0.10 | ||||||||||

| -204 | 3/8 | 1/8 | 0.359 | 0.005 | 0.139 | 0.004 | 9.12 | 0.13 | 3.53 | 0.10 | ||||||||||

| -205 | 7/16 | 1/8 | 0.421 | 0.005 | 0.139 | 0.004 | 10.69 | 0.13 | 3.53 | 0.10 | ||||||||||

| -206 | 1/2 | 1/8 | 0.484 | 0.005 | 0.139 | 0.004 | 12.29 | 0.13 | 3.53 | 0.10 | ||||||||||

| -207 | 9/16 | 1/8 | 0.546 | 0.007 | 0.139 | 0.004 | 13.87 | 0.18 | 3.53 | 0.10 | ||||||||||

| -208 | 5/8 | 1/8 | 0.609 | 0.009 | 0.139 | 0.004 | 15.47 | 0.23 | 3.53 | 0.10 | ||||||||||

| -209 | 11/16 | 1/8 | 0.671 | 0.009 | 0.139 | 0.004 | 17.04 | 0.23 | 3.53 | 0.10 | ||||||||||

| -210 | 3/4 | 1/8 | 0.734 | 0.010 | 0.139 | 0.004 | 18.64 | 0.25 | 3.53 | 0.10 | ||||||||||

| -211 | 13/16 | 1/8 | 0.796 | 0.010 | 0.139 | 0.004 | 20.22 | 0.25 | 3.53 | 0.10 | ||||||||||

| -212 | 7/8 | 1/8 | 0.859 | 0.010 | 0.139 | 0.004 | 21.82 | 0.25 | 3.53 | 0.10 | ||||||||||

| -213 | 15/16 | 1/8 | 0.921 | 0.010 | 0.139 | 0.004 | 23.39 | 0.25 | 3.53 | 0.10 | ||||||||||

| -214 | 1 | 1/8 | 0.984 | 0.010 | 0.139 | 0.004 | 24.99 | 0.25 | 3.53 | 0.10 | ||||||||||

| -215 | 1 1/16 | 1/8 | 1.046 | 0.010 | 0.139 | 0.004 | 26.57 | 0.25 | 3.53 | 0.10 | ||||||||||

| -216 | 1 1/8 | 1/8 | 1.109 | 0.012 | 0.139 | 0.004 | 28.17 | 0.30 | 3.53 | 0.10 | ||||||||||

| -217 | 1 3/16 | 1/8 | 1.171 | 0.012 | 0.139 | 0.004 | 29.74 | 0.30 | 3.53 | 0.10 | ||||||||||

| -218 | 1 1/4 | 1/8 | 1.234 | 0.012 | 0.139 | 0.004 | 31.34 | 0.30 | 3.53 | 0.10 | ||||||||||

| -219 | 1 5/16 | 1/8 | 1.296 | 0.012 | 0.139 | 0.004 | 32.92 | 0.30 | 3.53 | 0.10 | ||||||||||

| -220 | 1 3/8 | 1/8 | 1.359 | 0.012 | 0.139 | 0.004 | 34.52 | 0.30 | 3.53 | 0.10 | ||||||||||

| -221 | 1 7/16 | 1/8 | 1.421 | 0.012 | 0.139 | 0.004 | 36.09 | 0.30 | 3.53 | 0.10 | ||||||||||

| -222 | 1 1/2 | 1/8 | 1.484 | 0.015 | 0.139 | 0.004 | 37.69 | 0.38 | 3.53 | 0.10 | ||||||||||

| -223 | 1 5/8 | 1/8 | 1.609 | 0.015 | 0.139 | 0.004 | 40.87 | 0.38 | 3.53 | 0.10 | ||||||||||

| -224 | 1 3/4 | 1/8 | 1.734 | 0.015 | 0.139 | 0.004 | 44.04 | 0.38 | 3.53 | 0.10 | ||||||||||

| -225 | 1 7/8 | 1/8 | 1.859 | 0.018 | 0.139 | 0.004 | 47.22 | 0.46 | 3.53 | 0.10 | ||||||||||

| -226 | 2 | 1/8 | 1.984 | 0.018 | 0.139 | 0.004 | 50.39 | 0.46 | 3.53 | 0.10 | ||||||||||

| -227 | 2 1/8 | 1/8 | 2.109 | 0.018 | 0.139 | 0.004 | 53.57 | 0.46 | 3.53 | 0.10 | ||||||||||

| -228 | 2 1/4 | 1/8 | 2.234 | 0.020 | 0.139 | 0.004 | 56.74 | 0.51 | 3.53 | 0.10 | ||||||||||

| -229 | 2 3/8 | 1/8 | 2.359 | 0.020 | 0.139 | 0.004 | 59.92 | 0.51 | 3.53 | 0.10 | ||||||||||

| -230 | 2 1/2 | 1/8 | 2.484 | 0.020 | 0.139 | 0.004 | 63.09 | 0.51 | 3.53 | 0.10 | ||||||||||

| -231 | 2 5/8 | 1/8 | 2.609 | 0.020 | 0.139 | 0.004 | 66.27 | 0.51 | 3.53 | 0.10 | ||||||||||

| -232 | 2 3/4 | 1/8 | 2.734 | 0.024 | 0.139 | 0.004 | 69.44 | 0.61 | 3.53 | 0.10 | ||||||||||

| -233 | 2 7/8 | 1/8 | 2.859 | 0.024 | 0.139 | 0.004 | 72.62 | 0.61 | 3.53 | 0.10 | ||||||||||

| -234 | 3 | 1/8 | 2.984 | 0.024 | 0.139 | 0.004 | 75.79 | 0.61 | 3.53 | 0.10 | ||||||||||

| -235 | 3 1/8 | 1/8 | 3.109 | 0.024 | 0.139 | 0.004 | 78.97 | 0.61 | 3.53 | 0.10 | ||||||||||

| -236 | 3 1/4 | 1/8 | 3.234 | 0.024 | 0.139 | 0.004 | 82.14 | 0.61 | 3.53 | 0.10 | ||||||||||

| -237 | 3 3/8 | 1/8 | 3.359 | 0.024 | 0.139 | 0.004 | 85.32 | 0.61 | 3.53 | 0.10 | ||||||||||

| -238 | 3 1/2 | 1/8 | 3.484 | 0.024 | 0.139 | 0.004 | 88.49 | 0.61 | 3.53 | 0.10 | ||||||||||

| -239 | 3 5/8 | 1/8 | 3.609 | 0.028 | 0.139 | 0.004 | 91.67 | 0.71 | 3.53 | 0.10 | ||||||||||

| -240 | 3 3/4 | 1/8 | 3.734 | 0.028 | 0.139 | 0.004 | 94.84 | 0.71 | 3.53 | 0.10 | ||||||||||

| -241 | 3 7/8 | 1/8 | 3.859 | 0.028 | 0.139 | 0.004 | 98.02 | 0.71 | 3.53 | 0.10 | ||||||||||

| -242 | 4 | 1/8 | 3.984 | 0.028 | 0.139 | 0.004 | 101.19 | 0.71 | 3.53 | 0.10 | ||||||||||

| -243 | 4 1/8 | 1/8 | 4.109 | 0.028 | 0.139 | 0.004 | 104.37 | 0.71 | 3.53 | 0.10 | ||||||||||

| -244 | 4 1/4 | 1/8 | 4.234 | 0.030 | 0.139 | 0.004 | 107.54 | 0.76 | 3.53 | 0.10 | ||||||||||

| -245 | 4 3/8 | 1/8 | 4.359 | 0.030 | 0.139 | 0.004 | 110.72 | 0.76 | 3.53 | 0.10 | ||||||||||

| -246 | 4 1/2 | 1/8 | 4.484 | 0.030 | 0.139 | 0.004 | 113.89 | 0.76 | 3.53 | 0.10 | ||||||||||

| -247 | 4 5/8 | 1/8 | 4.609 | 0.030 | 0.139 | 0.004 | 117.07 | 0.76 | 3.53 | 0.10 | ||||||||||

| -248 | 4 3/4 | 1/8 | 4.734 | 0.030 | 0.139 | 0.004 | 120.24 | 0.76 | 3.53 | 0.10 | ||||||||||

| -249 | 4 7/8 | 1/8 | 4.859 | 0.035 | 0.139 | 0.004 | 123.42 | 0.89 | 3.53 | 0.10 | ||||||||||

| -250 | 5 | 1/8 | 4.984 | 0.035 | 0.139 | 0.004 | 126.59 | 0.89 | 3.53 | 0.10 | ||||||||||

| -251 | 5 1/8 | 1/8 | 5.109 | 0.035 | 0.139 | 0.004 | 129.77 | 0.89 | 3.53 | 0.10 | ||||||||||

| -252 | 5 1/4 | 1/8 | 5.234 | 0.035 | 0.139 | 0.004 | 132.94 | 0.89 | 3.53 | 0.10 | ||||||||||

| -253 | 5 3/8 | 1/8 | 5.359 | 0.035 | 0.139 | 0.004 | 136.12 | 0.89 | 3.53 | 0.10 | ||||||||||

| -254 | 5 1/2 | 1/8 | 5.484 | 0.035 | 0.139 | 0.004 | 139.29 | 0.89 | 3.53 | 0.10 | ||||||||||

| -255 | 5 5/8 | 1/8 | 5.609 | 0.035 | 0.139 | 0.004 | 142.47 | 0.89 | 3.53 | 0.10 | ||||||||||

| -256 | 5 3/4 | 1/8 | 5.734 | 0.035 | 0.139 | 0.004 | 145.64 | 0.89 | 3.53 | 0.10 | ||||||||||

| -257 | 5 7/8 | 1/8 | 5.859 | 0.035 | 0.139 | 0.004 | 148.82 | 0.89 | 3.53 | 0.10 | ||||||||||

| -258 | 6 | 1/8 | 5.984 | 0.035 | 0.139 | 0.004 | 151.99 | 0.89 | 3.53 | 0.10 | ||||||||||

| -259 | 6 1/4 | 1/8 | 6.234 | 0.040 | 0.139 | 0.004 | 158.34 | 1.02 | 3.53 | 0.10 | ||||||||||

| -260 | 6 1/2 | 1/8 | 6.484 | 0.040 | 0.139 | 0.004 | 164.69 | 1.02 | 3.53 | 0.10 | ||||||||||

| -261 | 6 3/4 | 1/8 | 6.734 | 0.040 | 0.139 | 0.004 | 171.04 | 1.02 | 3.53 | 0.10 | ||||||||||

| -262 | 7 | 1/8 | 6.984 | 0.040 | 0.139 | 0.004 | 177.39 | 1.02 | 3.53 | 0.10 | ||||||||||

| -263 | 7 1/4 | 1/8 | 7.234 | 0.045 | 0.139 | 0.004 | 183.74 | 1.14 | 3.53 | 0.10 | ||||||||||

| -264 | 7 1/2 | 1/8 | 7.484 | 0.045 | 0.139 | 0.004 | 190.09 | 1.14 | 3.53 | 0.10 | ||||||||||

| -265 | 7 3/4 | 1/8 | 7.734 | 0.045 | 0.139 | 0.004 | 196.44 | 1.14 | 3.53 | 0.10 | ||||||||||

| -266 | 8 | 1/8 | 7.984 | 0.045 | 0.139 | 0.004 | 202.79 | 1.14 | 3.53 | 0.10 | ||||||||||

| -267 | 8 1/4 | 1/8 | 8.234 | 0.050 | 0.139 | 0.004 | 209.14 | 1.27 | 3.53 | 0.10 | ||||||||||

| -268 | 8 1/2 | 1/8 | 8.484 | 0.050 | 0.139 | 0.004 | 215.49 | 1.27 | 3.53 | 0.10 | ||||||||||

| -269 | 8 3/4 | 1/8 | 8.734 | 0.050 | 0.139 | 0.004 | 221.84 | 1.27 | 3.53 | 0.10 | ||||||||||

| -270 | 9 | 1/8 | 8.984 | 0.050 | 0.139 | 0.004 | 228.19 | 1.27 | 3.53 | 0.10 | ||||||||||

| -271 | 9 1/4 | 1/8 | 9.234 | 0.055 | 0.139 | 0.004 | 234.54 | 1.40 | 3.53 | 0.10 | ||||||||||

| -272 | 9 1/2 | 1/8 | 9.484 | 0.055 | 0.139 | 0.004 | 240.89 | 1.40 | 3.53 | 0.10 | ||||||||||

| -273 | 9 3/4 | 1/8 | 9.734 | 0.055 | 0.139 | 0.004 | 247.24 | 1.40 | 3.53 | 0.10 | ||||||||||

| -274 | 10 | 1/8 | 9.984 | 0.055 | 0.139 | 0.004 | 253.59 | 1.40 | 3.53 | 0.10 | ||||||||||

| -275 | 10 1/2 | 1/8 | 10.484 | 0.055 | 0.139 | 0.004 | 266.29 | 1.40 | 3.53 | 0.10 | ||||||||||

| -276 | 11 | 1/8 | 10.984 | 0.065 | 0.139 | 0.004 | 278.99 | 1.65 | 3.53 | 0.10 | ||||||||||

| -277 | 11 1/2 | 1/8 | 11.484 | 0.065 | 0.139 | 0.004 | 291.69 | 1.65 | 3.53 | 0.10 | ||||||||||

| -278 | 12 | 1/8 | 11.984 | 0.065 | 0.139 | 0.004 | 304.39 | 1.65 | 3.53 | 0.10 | ||||||||||

| -279 | 13 | 1/8 | 12.984 | 0.065 | 0.139 | 0.004 | 329.79 | 1.65 | 3.53 | 0.10 | ||||||||||

| -280 | 14 | 1/8 | 13.984 | 0.065 | 0.139 | 0.004 | 355.19 | 1.65 | 3.53 | 0.10 | ||||||||||

| -281 | 15 | 1/8 | 14.984 | 0.065 | 0.139 | 0.004 | 380.59 | 1.65 | 3.53 | 0.10 | ||||||||||

| -282 | 16 | 1/8 | 15.955 | 0.075 | 0.139 | 0.004 | 405.26 | 1.91 | 3.53 | 0.10 | ||||||||||

| -283 | 17 | 1/8 | 16.955 | 0.080 | 0.139 | 0.004 | 430.66 | 2.03 | 3.53 | 0.10 | ||||||||||

| -284 | 18 | 1/8 | 17.955 | 0.085 | 0.139 | 0.004 | 456.06 | 2.16 | 3.53 | 0.10 | ||||||||||

| -309 | 7/16 | 3/16 | 0.412 | 0.005 | 0.210 | 0.005 | 10.46 | 0.13 | 5.33 | 0.13 | ||||||||||

| -310 | 1/2 | 3/16 | 0.475 | 0.005 | 0.210 | 0.005 | 12.07 | 0.13 | 5.33 | 0.13 | ||||||||||

| -311 | 9/16 | 3/16 | 0.537 | 0.007 | 0.210 | 0.005 | 13.64 | 0.18 | 5.33 | 0.13 | ||||||||||

| -312 | 5/8 | 3/16 | 0.600 | 0.009 | 0.210 | 0.005 | 15.24 | 0.23 | 5.33 | 0.13 | ||||||||||

| -313 | 11/16 | 3/16 | 0.662 | 0.009 | 0.210 | 0.005 | 16.81 | 0.23 | 5.33 | 0.13 | ||||||||||

| -314 | 3/4 | 3/16 | 0.725 | 0.010 | 0.210 | 0.005 | 18.42 | 0.25 | 5.33 | 0.13 | ||||||||||

| -315 | 13/16 | 3/16 | 0.787 | 0.010 | 0.210 | 0.005 | 19.99 | 0.25 | 5.33 | 0.13 | ||||||||||

| -316 | 7/8 | 3/16 | 0.850 | 0.010 | 0.210 | 0.005 | 21.59 | 0.25 | 5.33 | 0.13 | ||||||||||

| -317 | 15/16 | 3/16 | 0.912 | 0.010 | 0.210 | 0.005 | 23.16 | 0.25 | 5.33 | 0.13 | ||||||||||

| -318 | 1 | 3/16 | 0.975 | 0.010 | 0.210 | 0.005 | 24.77 | 0.25 | 5.33 | 0.13 | ||||||||||

| -319 | 1 1/16 | 3/16 | 1.037 | 0.010 | 0.210 | 0.005 | 26.34 | 0.25 | 5.33 | 0.13 | ||||||||||

| -320 | 1 1/8 | 3/16 | 1.100 | 0.012 | 0.210 | 0.005 | 27.94 | 0.30 | 5.33 | 0.13 | ||||||||||

| -321 | 1 3/16 | 3/16 | 1.162 | 0.012 | 0.210 | 0.005 | 29.51 | 0.30 | 5.33 | 0.13 | ||||||||||

| -322 | 1 1/4 | 3/16 | 1.225 | 0.012 | 0.210 | 0.005 | 31.12 | 0.30 | 5.33 | 0.13 | ||||||||||

| -323 | 1 5/16 | 3/16 | 1.287 | 0.012 | 0.210 | 0.005 | 32.69 | 0.30 | 5.33 | 0.13 | ||||||||||

| -324 | 1 3/8 | 3/16 | 1.350 | 0.012 | 0.210 | 0.005 | 34.29 | 0.30 | 5.33 | 0.13 | ||||||||||

| -325 | 1 1/2 | 3/16 | 1.475 | 0.015 | 0.210 | 0.005 | 37.47 | 0.38 | 5.33 | 0.13 | ||||||||||

| -326 | 1 5/8 | 3/16 | 1.600 | 0.015 | 0.210 | 0.005 | 40.64 | 0.38 | 5.33 | 0.13 | ||||||||||

| -327 | 1 3/4 | 3/16 | 1.725 | 0.015 | 0.210 | 0.005 | 43.82 | 0.38 | 5.33 | 0.13 | ||||||||||

| -328 | 1 7/8 | 3/16 | 1.850 | 0.015 | 0.210 | 0.005 | 46.99 | 0.38 | 5.33 | 0.13 | ||||||||||

| -329 | 2 | 3/16 | 1.975 | 0.018 | 0.210 | 0.005 | 50.17 | 0.46 | 5.33 | 0.13 | ||||||||||

| -330 | 2 1/8 | 3/16 | 2.100 | 0.018 | 0.210 | 0.005 | 53.34 | 0.46 | 5.33 | 0.13 | ||||||||||

| -331 | 2 1/4 | 3/16 | 2.225 | 0.018 | 0.210 | 0.005 | 56.52 | 0.46 | 5.33 | 0.13 | ||||||||||

| -332 | 2 3/8 | 3/16 | 2.350 | 0.018 | 0.210 | 0.005 | 59.69 | 0.46 | 5.33 | 0.13 | ||||||||||

| -333 | 2 1/2 | 3/16 | 2.475 | 0.020 | 0.210 | 0.005 | 62.87 | 0.51 | 5.33 | 0.13 | ||||||||||

| -334 | 2 5/8 | 3/16 | 2.600 | 0.020 | 0.210 | 0.005 | 66.04 | 0.51 | 5.33 | 0.13 | ||||||||||

| -335 | 2 3/4 | 3/16 | 2.725 | 0.020 | 0.210 | 0.005 | 69.22 | 0.51 | 5.33 | 0.13 | ||||||||||

| -336 | 2 7/8 | 3/16 | 2.850 | 0.020 | 0.210 | 0.005 | 72.39 | 0.51 | 5.33 | 0.13 | ||||||||||

| -337 | 3 | 3/16 | 2.975 | 0.024 | 0.210 | 0.005 | 75.57 | 0.61 | 5.33 | 0.13 | ||||||||||

| -338 | 3 1/8 | 3/16 | 3.100 | 0.024 | 0.210 | 0.005 | 78.74 | 0.61 | 5.33 | 0.13 | ||||||||||

| -339 | 3 1/4 | 3/16 | 3.225 | 0.024 | 0.210 | 0.005 | 81.92 | 0.61 | 5.33 | 0.13 | ||||||||||

| -340 | 3 3/8 | 3/16 | 3.350 | 0.024 | 0.210 | 0.005 | 85.09 | 0.61 | 5.33 | 0.13 | ||||||||||

| -341 | 3 1/2 | 3/16 | 3.475 | 0.024 | 0.210 | 0.005 | 88.27 | 0.61 | 5.33 | 0.13 | ||||||||||

| -342 | 3 5/8 | 3/16 | 3.600 | 0.028 | 0.210 | 0.005 | 91.44 | 0.71 | 5.33 | 0.13 | ||||||||||

| -343 | 3 3/4 | 3/16 | 3.725 | 0.028 | 0.210 | 0.005 | 94.62 | 0.71 | 5.33 | 0.13 | ||||||||||

| -344 | 3 7/8 | 3/16 | 3.850 | 0.028 | 0.210 | 0.005 | 97.79 | 0.71 | 5.33 | 0.13 | ||||||||||

| -345 | 4 | 3/16 | 3.975 | 0.028 | 0.210 | 0.005 | 100.97 | 0.71 | 5.33 | 0.13 | ||||||||||

| -346 | 4 1/8 | 3/16 | 4.100 | 0.028 | 0.210 | 0.005 | 104.14 | 0.71 | 5.33 | 0.13 | ||||||||||

| -347 | 4 1/4 | 3/16 | 4.225 | 0.030 | 0.210 | 0.005 | 107.32 | 0.76 | 5.33 | 0.13 | ||||||||||

| -348 | 4 3/8 | 3/16 | 4.350 | 0.030 | 0.210 | 0.005 | 110.49 | 0.76 | 5.33 | 0.13 | ||||||||||

| -349 | 4 1/2 | 3/16 | 4.475 | 0.030 | 0.210 | 0.005 | 113.67 | 0.76 | 5.33 | 0.13 | ||||||||||

| -350 | 4 5/8 | 3/16 | 4.600 | 0.030 | 0.210 | 0.005 | 116.84 | 0.76 | 5.33 | 0.13 | ||||||||||

| -351 | 4 3/4 | 3/16 | 4.725 | 0.030 | 0.210 | 0.005 | 120.02 | 0.76 | 5.33 | 0.13 | ||||||||||

| -352 | 4 7/8 | 3/16 | 4.850 | 0.030 | 0.210 | 0.005 | 123.19 | 0.76 | 5.33 | 0.13 | ||||||||||

| -353 | 5 | 3/16 | 4.975 | 0.037 | 0.210 | 0.005 | 126.37 | 0.94 | 5.33 | 0.13 | ||||||||||

| -354 | 5 1/8 | 3/16 | 5.100 | 0.037 | 0.210 | 0.005 | 129.54 | 0.94 | 5.33 | 0.13 | ||||||||||

| -355 | 5 1/4 | 3/16 | 5.225 | 0.037 | 0.210 | 0.005 | 132.72 | 0.94 | 5.33 | 0.13 | ||||||||||

| -356 | 5 3/8 | 3/16 | 5.350 | 0.037 | 0.210 | 0.005 | 135.89 | 0.94 | 5.33 | 0.13 | ||||||||||

| -357 | 5 1/2 | 3/16 | 5.475 | 0.037 | 0.210 | 0.005 | 139.07 | 0.94 | 5.33 | 0.13 | ||||||||||

| -358 | 5 5/8 | 3/16 | 5.600 | 0.037 | 0.210 | 0.005 | 142.24 | 0.94 | 5.33 | 0.13 | ||||||||||

| -359 | 5 3/4 | 3/16 | 5.725 | 0.037 | 0.210 | 0.005 | 145.42 | 0.94 | 5.33 | 0.13 | ||||||||||

| -360 | 5 7/8 | 3/16 | 5.850 | 0.037 | 0.210 | 0.005 | 148.59 | 0.94 | 5.33 | 0.13 | ||||||||||

| -361 | 6 | 3/16 | 5.975 | 0.037 | 0.210 | 0.005 | 151.77 | 0.94 | 5.33 | 0.13 | ||||||||||

| -362 | 6 1/4 | 3/16 | 6.225 | 0.040 | 0.210 | 0.005 | 158.12 | 1.02 | 5.33 | 0.13 | ||||||||||

| -363 | 6 1/2 | 3/16 | 6.475 | 0.040 | 0.210 | 0.005 | 164.47 | 1.02 | 5.33 | 0.13 | ||||||||||

| -364 | 6 3/4 | 3/16 | 6.725 | 0.040 | 0.210 | 0.005 | 170.82 | 1.02 | 5.33 | 0.13 | ||||||||||

| -365 | 7 | 3/16 | 6.975 | 0.040 | 0.210 | 0.005 | 177.17 | 1.02 | 5.33 | 0.13 | ||||||||||

| -366 | 7 1/4 | 3/16 | 7.225 | 0.045 | 0.210 | 0.005 | 183.52 | 1.14 | 5.33 | 0.13 | ||||||||||

| -367 | 7 1/2 | 3/16 | 7.475 | 0.045 | 0.210 | 0.005 | 189.87 | 1.14 | 5.33 | 0.13 | ||||||||||

| -368 | 7 3/4 | 3/16 | 7.725 | 0.045 | 0.210 | 0.005 | 196.22 | 1.14 | 5.33 | 0.13 | ||||||||||

| -369 | 8 | 3/16 | 7.975 | 0.045 | 0.210 | 0.005 | 202.57 | 1.14 | 5.33 | 0.13 | ||||||||||

| -370 | 8 1/4 | 3/16 | 8.225 | 0.050 | 0.210 | 0.005 | 208.92 | 1.27 | 5.33 | 0.13 | ||||||||||

| -371 | 8 1/2 | 3/16 | 8.475 | 0.050 | 0.210 | 0.005 | 215.27 | 1.27 | 5.33 | 0.13 | ||||||||||

| -372 | 8 3/4 | 3/16 | 8.725 | 0.050 | 0.210 | 0.005 | 221.62 | 1.27 | 5.33 | 0.13 | ||||||||||

| -373 | 9 | 3/16 | 8.975 | 0.050 | 0.210 | 0.005 | 227.97 | 1.27 | 5.33 | 0.13 | ||||||||||

| -374 | 9 1/4 | 3/16 | 9.225 | 0.055 | 0.210 | 0.005 | 234.32 | 1.40 | 5.33 | 0.13 | ||||||||||

| -375 | 9 1/2 | 3/16 | 9.475 | 0.055 | 0.210 | 0.005 | 240.67 | 1.40 | 5.33 | 0.13 | ||||||||||

| -376 | 9 3/4 | 3/16 | 9.725 | 0.055 | 0.210 | 0.005 | 247.02 | 1.40 | 5.33 | 0.13 | ||||||||||

| -377 | 10 | 3/16 | 9.975 | 0.055 | 0.210 | 0.005 | 253.37 | 1.40 | 5.33 | 0.13 | ||||||||||

| -378 | 10 1/2 | 3/16 | 10.475 | 0.060 | 0.210 | 0.005 | 266.07 | 1.52 | 5.33 | 0.13 | ||||||||||

| -379 | 11 | 3/16 | 10.975 | 0.060 | 0.210 | 0.005 | 278.77 | 1.52 | 5.33 | 0.13 | ||||||||||

| -380 | 11 1/2 | 3/16 | 11.475 | 0.065 | 0.210 | 0.005 | 291.47 | 1.65 | 5.33 | 0.13 | ||||||||||

| -381 | 12 | 3/16 | 11.975 | 0.065 | 0.210 | 0.005 | 304.17 | 1.65 | 5.33 | 0.13 | ||||||||||

| -382 | 13 | 3/16 | 12.975 | 0.065 | 0.210 | 0.005 | 329.57 | 1.65 | 5.33 | 0.13 | ||||||||||

| -383 | 14 | 3/16 | 13.975 | 0.070 | 0.210 | 0.005 | 354.97 | 1.78 | 5.33 | 0.13 | ||||||||||

| -384 | 15 | 3/16 | 14.975 | 0.070 | 0.210 | 0.005 | 380.37 | 1.78 | 5.33 | 0.13 | ||||||||||

| -385 | 16 | 3/16 | 15.955 | 0.075 | 0.210 | 0.005 | 405.26 | 1.91 | 5.33 | 0.13 | ||||||||||

| -386 | 17 | 3/16 | 16.955 | 0.080 | 0.210 | 0.005 | 430.66 | 2.03 | 5.33 | 0.13 | ||||||||||

| -387 | 18 | 3/16 | 17.955 | 0.085 | 0.210 | 0.005 | 456.06 | 2.16 | 5.33 | 0.13 | ||||||||||

| -388 | 19 | 3/16 | 18.955 | 0.090 | 0.210 | 0.005 | 481.45 | 2.29 | 5.33 | 0.13 | ||||||||||

| -389 | 20 | 3/16 | 19.955 | 0.095 | 0.210 | 0.005 | 506.85 | 2.41 | 5.33 | 0.13 | ||||||||||

| -390 | 21 | 3/16 | 20.955 | 0.095 | 0.210 | 0.005 | 532.25 | 2.41 | 5.33 | 0.13 | ||||||||||

| -391 | 22 | 3/16 | 21.955 | 0.100 | 0.210 | 0.005 | 557.65 | 2.54 | 5.33 | 0.13 | ||||||||||

| -392 | 23 | 3/16 | 22.940 | 0.105 | 0.210 | 0.005 | 582.68 | 2.67 | 5.33 | 0.13 | ||||||||||

| -393 | 24 | 3/16 | 23.940 | 0.110 | 0.210 | 0.005 | 608.08 | 2.79 | 5.33 | 0.13 | ||||||||||

| -394 | 25 | 3/16 | 24.940 | 0.115 | 0.210 | 0.005 | 633.48 | 2.92 | 5.33 | 0.13 | ||||||||||

| -395 | 26 | 3/16 | 25.940 | 0.120 | 0.210 | 0.005 | 658.88 | 3.05 | 5.33 | 0.13 | ||||||||||

| -425 | 4 1/2 | 1/4 | 4.475 | 0.033 | 0.275 | 0.006 | 113.67 | 0.84 | 6.99 | 0.15 | ||||||||||

| -426 | 4 5/8 | 1/4 | 4.600 | 0.033 | 0.275 | 0.006 | 116.84 | 0.84 | 6.99 | 0.15 | ||||||||||

| -427 | 4 3/4 | 1/4 | 4.725 | 0.033 | 0.275 | 0.006 | 120.02 | 0.84 | 6.99 | 0.15 | ||||||||||

| -428 | 4 7/8 | 1/4 | 4.850 | 0.033 | 0.275 | 0.006 | 123.19 | 0.84 | 6.99 | 0.15 | ||||||||||

| -429 | 5 | 1/4 | 4.975 | 0.037 | 0.275 | 0.006 | 126.37 | 0.94 | 6.99 | 0.15 | ||||||||||

| -430 | 5 1/8 | 1/4 | 5.100 | 0.037 | 0.275 | 0.006 | 129.54 | 0.94 | 6.99 | 0.15 | ||||||||||

| -431 | 5 1/4 | 1/4 | 5.225 | 0.037 | 0.275 | 0.006 | 132.72 | 0.94 | 6.99 | 0.15 | ||||||||||

| -432 | 5 3/8 | 1/4 | 5.350 | 0.037 | 0.275 | 0.006 | 135.89 | 0.94 | 6.99 | 0.15 | ||||||||||

| -433 | 5 1/2 | 1/4 | 5.475 | 0.037 | 0.275 | 0.006 | 139.07 | 0.94 | 6.99 | 0.15 | ||||||||||

| -434 | 5 5/8 | 1/4 | 5.600 | 0.037 | 0.275 | 0.006 | 142.24 | 0.94 | 6.99 | 0.15 | ||||||||||

| -435 | 5 3/4 | 1/4 | 5.725 | 0.037 | 0.275 | 0.006 | 145.42 | 0.94 | 6.99 | 0.15 | ||||||||||

| -436 | 5 7/8 | 1/4 | 5.850 | 0.037 | 0.275 | 0.006 | 148.59 | 0.94 | 6.99 | 0.15 | ||||||||||

| -437 | 6 | 1/4 | 5.975 | 0.037 | 0.275 | 0.006 | 151.77 | 0.94 | 6.99 | 0.15 | ||||||||||

| -438 | 6 1/4 | 1/4 | 6.225 | 0.040 | 0.275 | 0.006 | 158.12 | 1.02 | 6.99 | 0.15 | ||||||||||

| -439 | 6 1/2 | 1/4 | 6.475 | 0.040 | 0.275 | 0.006 | 164.47 | 1.02 | 6.99 | 0.15 | ||||||||||

| -440 | 6 3/4 | 1/4 | 6.725 | 0.040 | 0.275 | 0.006 | 170.82 | 1.02 | 6.99 | 0.15 | ||||||||||

| -441 | 7 | 1/4 | 6.975 | 0.040 | 0.275 | 0.006 | 177.17 | 1.02 | 6.99 | 0.15 | ||||||||||

| -442 | 7 1/4 | 1/4 | 7.225 | 0.045 | 0.275 | 0.006 | 183.52 | 1.14 | 6.99 | 0.15 | ||||||||||

| -443 | 7 1/2 | 1/4 | 7.475 | 0.045 | 0.275 | 0.006 | 189.87 | 1.14 | 6.99 | 0.15 | ||||||||||

| -444 | 7 3/4 | 1/4 | 7.725 | 0.045 | 0.275 | 0.006 | 196.22 | 1.14 | 6.99 | 0.15 | ||||||||||

| -445 | 8 | 1/4 | 7.975 | 0.045 | 0.275 | 0.006 | 202.57 | 1.14 | 6.99 | 0.15 | ||||||||||

| -446 | 8 1/2 | 1/4 | 8.475 | 0.055 | 0.275 | 0.006 | 215.27 | 1.40 | 6.99 | 0.15 | ||||||||||

| -447 | 9 | 1/4 | 8.975 | 0.055 | 0.275 | 0.006 | 227.97 | 1.40 | 6.99 | 0.15 | ||||||||||

| -448 | 9 1/2 | 1/4 | 9.475 | 0.055 | 0.275 | 0.006 | 240.67 | 1.40 | 6.99 | 0.15 | ||||||||||

| -449 | 10 | 1/4 | 9.975 | 0.055 | 0.275 | 0.006 | 253.37 | 1.40 | 6.99 | 0.15 | ||||||||||

| -450 | 10 1/2 | 1/4 | 10.475 | 0.060 | 0.275 | 0.006 | 266.07 | 1.52 | 6.99 | 0.15 | ||||||||||

| -451 | 11 | 1/4 | 10.975 | 0.060 | 0.275 | 0.006 | 278.77 | 1.52 | 6.99 | 0.15 | ||||||||||

| -452 | 11 1/2 | 1/4 | 11.475 | 0.060 | 0.275 | 0.006 | 291.47 | 1.52 | 6.99 | 0.15 | ||||||||||

| -453 | 12 | 1/4 | 11.975 | 0.060 | 0.275 | 0.006 | 304.17 | 1.52 | 6.99 | 0.15 | ||||||||||

| -454 | 12 1/2 | 1/4 | 12.475 | 0.060 | 0.275 | 0.006 | 316.87 | 1.52 | 6.99 | 0.15 | ||||||||||

| -455 | 13 | 1/4 | 12.975 | 0.060 | 0.275 | 0.006 | 329.57 | 1.52 | 6.99 | 0.15 | ||||||||||

| -456 | 13 1/2 | 1/4 | 13.475 | 0.070 | 0.275 | 0.006 | 342.27 | 1.78 | 6.99 | 0.15 | ||||||||||

| -457 | 14 | 1/4 | 13.975 | 0.070 | 0.275 | 0.006 | 354.97 | 1.78 | 6.99 | 0.15 | ||||||||||

| -458 | 14 1/2 | 1/4 | 14.475 | 0.070 | 0.275 | 0.006 | 367.67 | 1.78 | 6.99 | 0.15 | ||||||||||

| -459 | 15 | 1/4 | 14.975 | 0.070 | 0.275 | 0.006 | 380.37 | 1.78 | 6.99 | 0.15 | ||||||||||

| -460 | 15 1/2 | 1/4 | 15.475 | 0.070 | 0.275 | 0.006 | 393.07 | 1.78 | 6.99 | 0.15 | ||||||||||

| -461 | 16 | 1/4 | 15.955 | 0.075 | 0.275 | 0.006 | 405.26 | 1.91 | 6.99 | 0.15 | ||||||||||

| -462 | 16 1/2 | 1/4 | 16.455 | 0.075 | 0.275 | 0.006 | 417.96 | 1.91 | 6.99 | 0.15 | ||||||||||

| -463 | 17 | 1/4 | 16.955 | 0.080 | 0.275 | 0.006 | 430.66 | 2.03 | 6.99 | 0.15 | ||||||||||

| -464 | 17 1/2 | 1/4 | 17.455 | 0.085 | 0.275 | 0.006 | 443.36 | 2.16 | 6.99 | 0.15 | ||||||||||

| -465 | 18 | 1/4 | 17.955 | 0.085 | 0.275 | 0.006 | 456.06 | 2.16 | 6.99 | 0.15 | ||||||||||

| -466 | 18 1/2 | 1/4 | 18.455 | 0.085 | 0.275 | 0.006 | 468.76 | 2.16 | 6.99 | 0.15 | ||||||||||

| -467 | 19 | 1/4 | 18.955 | 0.090 | 0.275 | 0.006 | 481.46 | 2.29 | 6.99 | 0.15 | ||||||||||

| -468 | 19 1/2 | 1/4 | 19.455 | 0.090 | 0.275 | 0.006 | 494.16 | 2.29 | 6.99 | 0.15 | ||||||||||

| -469 | 20 | 1/4 | 19.955 | 0.095 | 0.275 | 0.006 | 506.86 | 2.41 | 6.99 | 0.15 | ||||||||||

| -470 | 21 | 1/4 | 20.955 | 0.095 | 0.275 | 0.006 | 532.26 | 2.41 | 6.99 | 0.15 | ||||||||||

| -471 | 22 | 1/4 | 21.955 | 0.100 | 0.275 | 0.006 | 557.66 | 2.54 | 6.99 | 0.15 | ||||||||||

| -472 | 23 | 1/4 | 22.940 | 0.105 | 0.275 | 0.006 | 582.68 | 2.67 | 6.99 | 0.15 | ||||||||||

| -473 | 24 | 1/4 | 23.940 | 0.110 | 0.275 | 0.006 | 608.08 | 2.79 | 6.99 | 0.15 | ||||||||||

| -474 | 25 | 1/4 | 24.940 | 0.115 | 0.275 | 0.006 | 633.48 | 2.92 | 6.99 | 0.15 | ||||||||||

| -475 | 26 | 1/4 | 25.940 | 0.120 | 0.275 | 0.006 | 658.88 | 3.05 | 6.99 | 0.15 | ||||||||||

| AS568 SIZE | Nominal ID | Chiyero ID in inches | ±ID | Zviyero CS mumasendimita | ±CS | Chiyero ID mu mm | ±ID | Zviyero CS mu mm | ± C/S | |||||||||||

| -901 | 3/32 | 0.185 | 0.005 | 0.056 | 0.003 | 4.70 | 0.13 | 1.42 | 0.08 | |||||||||||

| -902 | 1/8 | 0.239 | 0.005 | 0.064 | 0.003 | 6.07 | 0.13 | 1.63 | 0.08 | |||||||||||

| -903 | 3/16 | 0.301 | 0.005 | 0.064 | 0.003 | 7.65 | 0.13 | 1.63 | 0.08 | |||||||||||

| -904 | 1/4 | 0.351 | 0.005 | 0.072 | 0.003 | 8.92 | 0.13 | 1.83 | 0.08 | |||||||||||

| -905 | 5/16 | 0.414 | 0.005 | 0.072 | 0.003 | 10.52 | 0.13 | 1.83 | 0.08 | |||||||||||

| -906 | 3/8 | 0.468 | 0.005 | 0.078 | 0.003 | 11.89 | 0.13 | 1.98 | 0.08 | |||||||||||

| -907 | 7/16 | 0.530 | 0.007 | 0.082 | 0.003 | 13.46 | 0.18 | 2.08 | 0.08 | |||||||||||

| -908 | 1/2 | 0.644 | 0.009 | 0.087 | 0.003 | 16.36 | 0.23 | 2.21 | 0.08 | |||||||||||

| -909 | 9/16 | 0.706 | 0.009 | 0.097 | 0.003 | 17.93 | 0.23 | 2.46 | 0.08 | |||||||||||

| -910 | 5/8 | 0.755 | 0.009 | 0.097 | 0.003 | 19.18 | 0.23 | 2.46 | 0.08 | |||||||||||

| -911 | 11/16 | 0.863 | 0.009 | 0.116 | 0.004 | 21.92 | 0.23 | 2.95 | 0.10 | |||||||||||

| -912 | 3/4 | 0.924 | 0.009 | 0.116 | 0.004 | 23.47 | 0.23 | 2.95 | 0.10 | |||||||||||

| -913 | 13/16 | 0.986 | 0.010 | 0.116 | 0.004 | 25.04 | 0.25 | 2.95 | 0.10 | |||||||||||

| -914 | 7/8 | 1.047 | 0.010 | 0.116 | 0.004 | 26.59 | 0.25 | 2.95 | 0.10 | |||||||||||

| -916 | 1 | 1.171 | 0.010 | 0.116 | 0.004 | 29.74 | 0.25 | 2.95 | 0.10 | |||||||||||

| -918 | 1 1/8 | 1.355 | 0.012 | 0.116 | 0.004 | 34.42 | 0.30 | 2.95 | 0.10 | |||||||||||

| -920 | 1 1/4 | 1.475 | 0.014 | 0.118 | 0.004 | 37.47 | 0.36 | 3.00 | 0.10 | |||||||||||

| -924 | 1 1/2 | 1.720 | 0.014 | 0.118 | 0.004 | 43.69 | 0.36 | 3.00 | 0.10 | |||||||||||

| -928 | 1 3/4 | 2.090 | 0.018 | 0.118 | 0.004 | 53.09 | 0.46 | 3.00 | 0.10 | |||||||||||

| -932 | 2 | 2.337 | 0.018 | 0.118 | 0.004 | 59.36 | 0.46 | 3.00 | 0.10 | |||||||||||

Chechipiri -Compression rate uye kutambanudza chiyero cheorings

Iyo O-mhete ndeye yakajairwa extruded chisimbiso.The compression reshiyo uye kutambanudza chiyero chechidimbu-chikamu dhayamita yeO-ring ndizvo zvikuru zviri mukati mekugadzira chisimbiso, izvo zvine kukosha kukuru kwekuisa chisimbiso kuita uye hupenyu hwesevhisi.Iyo yakanaka yekuisa chisimbiso mhedzisiro yeO-mhete zvakanyanya zvinoenderana nekuenderana kwakaringana kweO-ring saizi uye groove saizi, kugadzira kumanikidza kunonzwisisika uye kutambanudza huwandu hwechisimbiso mhete.

1. Compression rate

Iyo compression rate W inowanzo kuratidzwa seinotevera:

W=(d0 h)/d0× 100%

Muchigadziro, d0- dhiyabhorosi-sectional dhayamita yeO-ring mune yakasununguka mamiriro (mm);

H - Chinhambwe chiri pakati pepasi peO-ring groove nenzvimbo yakavharwa (groove kudzika), kureva kureba kwechikamu cheO-ring mushure mekudzvanywa (mm)

2.Pakusarudza iyo yekumanikidza reshiyo yeO-ring, zvinotevera zvinhu zvitatu zvinofanirwa kutariswa:

(1).Panofanira kuva nenzvimbo yekubatanidza yekuisa chisimbiso yakakwana;(2).Edza kuderedza simba rekukwenya;(3).Edza kudzivisa deformation zvachose.

Hazvina kuoma kuona kubva pamusoro apa kuti pane kupesana pakati pazvo.Iyo yakanyanya kudzvanywa mwero inogona kuwana yakakwira yekubata kudzvanywa, asi yakawandisa yekumanikidza mwero pasina mubvunzo inowedzera kutsvedza kukweshera uye deformation zvachose.Kana chiyero chekumanikidza chiri chidiki zvakanyanya, chinogona kunge chiri nekuda kwekukanganisa kwe coaxiality uye O-ring kukanganisa kwechisimbiso groove kusasangana nezvinodiwa, zvichikonzera kutsakatika kweimwe chiyero chekumanikidza uye kukonzera kudonha.Nokudaro, pakusarudza chiyero chekumanikidza cheO-ring, zvakakosha kuyera zvinhu zvakasiyana-siyana.Kazhinji, chiyero chekumanikidza chezvisimbiso zvakamira chakakura kupfuura chezvisimbiso zvine simba, asi kukosha kwayo kwakanyanya kunofanirwa kunge kuri pasi pe25%.Zvikasadaro, iyo compression stress ichanyanya kuzorora uye yakawandisa kusingaperi deformation ichaitika, kunyanya mumamiriro ekupisa ekushanda.Sarudzo yekumanikidza reshiyo W yeO-ring seals inofanirwa kufunga nezvemamiriro ekushandiswa, akadai seakamira kana dynamic seals;Kuiswa chisimbiso kwakasimba kunogona kukamurwa kuita radial sealing uye axial sealing;Iyo gap yekuvuza yeradial zvisimbiso (kana cylindrical static seals) ndiyo gap reradial, nepo gap rekuvuza reaxial seals (kana planar static seals) ndiyo axial gap.Axial sealing yakakamurwa kuita mamiriro maviri zvichienderana nekuti iyo yekumanikidza svikiro inoshanda padhayamita yemukati kana yekunze dhayamita yeO-ring: kumanikidza kwemukati uye kumanikidza kwekunze.Kuwedzera kwekumanikidzwa kwemukati kunotungamirira kutambanudza, asi kunze kwekunze kunoderedza kutambanudza kwekutanga kweO-ring.Mhando dzakasiyana dzezvisimbiso dzakamira dzataurwa pamusoro dzine nzira dzakasiyana dzekuita zvechisimbiso chepakati paO-ring, saka pre pressure dhizaini zvakare yakasiyana.Kune zvisimbiso zvine simba, zvinodikanwa kusiyanisa pakati pezvisimbiso zvinodzokorora zvinofamba uye zvisimbiso zvinotenderera.

(2).Kusunga chisimbiso: Kufanana nemidziyo yekuisa chisimbiso inodzokororwa, cylindrical static yekuisa chisimbiso kazhinji inotora W=10% kusvika 15%;Iyo flat static yekuisa chisimbiso mudziyo inotora W = 15% ~ 30%.Nekusimbisa chisimbiso, inogona kukamurwa kuita mamiriro matatu;Iko kudzoreredza kufamba kunowanzo kutorwa seW = 10% kusvika 15%.Paunenge uchisarudza iyo yekumanikidza reshiyo yeinotenderera inofamba zvisimbiso, iyo Joule kupisa mhedzisiro inofanirwa kutariswa.Kazhinji, dhayamita yemukati yeO-ring inoshandiswa pakutenderera inosvika 3% -5% yakakura kudarika shaft dhayamita, uye chiyero chekumanikidza chedhayamita yekunze W=3% -8%.Pamitambo yekukweshana yakaderera, maO-mhete anowanzo kusarudzwa ane diki compression reshiyo yeW = 5% -8% kuitira kuderedza frictional resistance.Mukuwedzera, kuwedzera kwezvinhu zverubha zvinokonzerwa nepakati uye tembiricha inofanirawo kutariswa.Kazhinji, kupfuura iyo yakapihwa compression deformation, iyo yakanyanya kubvumidzwa chiyero chekuwedzera i15%.Kupfuura mutsara uyu kunoratidza kuti kusarudzwa kwezvinhu hakuna kukodzera, uye O-mhete dzezvimwe zvinhu dzinofanira kushandiswa panzvimbo, kana iyo yakapihwa compression deformation rate inofanirwa kugadziriswa.

(3)Kutambanudza mari,Mushure mekuiswa mugirovha yekuisa chisimbiso, iyo O-ring kazhinji ine imwe chiyero chekutambanudza.Kufanana nehuwandu hwekumanikidza, huwandu hwekutambanudza zvakare hune mhedzisiro yakakosha pakuita chisimbiso uye hupenyu hwesevhisi yeO-ring.Kuwanda kukuru kwekutambanudza kwete kungoita kuti zviome kuisa O-ring, asi zvakare inoderedza chiyero chekumanikidza nekuda kwekuchinja kwepakati-chikamu dhayamita d0, zvichiita kuti pave nekudonha.Iyo yekutambanudza mari inogona kuratidzwa sezvinotevera:α= (d+d0)/(d1+d0)Muchidimbu, d - shaft dhayamita (mm);D1-- Inner dhayamita yeO-ring (mm).Nhamba yekutambanudza chiyero ndeye 1% -5%.Maitiro akakurudzirwa ehuwandu hwekutambanudza kweO-ring anopiwa mutafura.Nhamba yakatambanudzwa yeO-ring inogona kusarudzwa maererano nehukuru hweshaft dhayamita zvichienderana netafura yekusarudza muganhu.Precedence range ye compression ratio uye kutambanudza huwandu hweO-ring

Chechitatu-hukama pakati pedhayamita yemukati (ID), dhayamita rekunze (OD), uye dhayamita yewaya (C/S) yeO-ring.

OD=ID+C/S*2 Zvakadai se: ID=3MM C/S=1MM OD=3MM+1*2=5MM

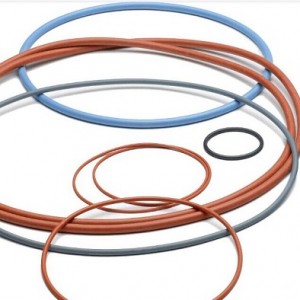

Yechina-Zvinhu zvinowanzoshandiswa mukugadzirwa kweO-mhete

- NBR :NBR O-RING

ine yakanakisa kupikisa mafuta, benzene resistance, heat resistance, uye hunhu hwemuviri nemakanika, uye ndeimwe yezvinhu zvakajairika zvezvigadzirwa zverabha zvinodzivirira mafuta.Inoshandiswa zvakanyanya mukugadzira mafuta anodzivirira gaskets, gaskets, hose yerabha, mabhokisi etsamba endege, flexible packaging, kudhinda uye dhayi rabha rollers, cable zvinhu, uye zvinonamira.

- EPDM:EPDM O-RING

ine yakanakisa mechanical zvivakwa, makemikari kuramba, uye kupisa kuramba, ukuwo kuratidza yakasimba mamiriro ekunze kuramba.Ethylene propylene diene monomer (EPDM) inoratidza zvakanakisa zvivakwa maererano neozone kuramba, kupisa kupisa, kuramba kwemamiriro ekunze, uye kupfava kwakaderera, zvichiita kuti ive yakakodzera kune maapplication anodzivirira ozone, kusagadzikana kwemamiriro ekunze, uye UV kusagadzikana.Nekudaro, nekuda kwehunhu hwayo hwekuita, kudzoreredza kwemurazvo, kuramba mafuta, uye kunamatira kweEPDM rabha kune hurombo.Zvakadaro, iyi mhando yerabha ine main cheni yakazadzwa chimiro uye inogona kusanganiswa nezvimwe zvinhu kuvandudza mashandiro kuburikidza nekudzidza kubva kune umwe neumwe kusimba uye kusasimba.

- VMQ(SILICONE):SILICONE O-RING

neTembiricha uye mafuta kuramba.Silicone rabha ine yakanaka yakaderera-tembiricha kuramba uye inogona kushanda kazhinji pa -55℃.Mushure mekuiswa kwe phenyl, inogona kusvika -73℃.Kupisa kwekupokana kwesilicone rabha zvakare kwakatanhamara, uye inogona kushanda kwenguva yakareba pa180℃.Inogona kumira mavhiki akati wandei kana kupfuura e elasticity kunyangwe iri pamusoro pe200℃, uye inogona kumira pakarepo tembiricha yepamusoro inopfuura 300℃.Silicone rabha ine kufema kwakanaka uye iyo oxygen permeability ndiyo yakanyanya pakati pemapolymer ekugadzira.Uye zvakare, silicone rabha inewo yakakurumbira hunhu hwekusagadzikana kwemuviri uye haikonzeri coagulation, ichiita kuti ishandiswe zvakanyanya munharaunda yekurapa.

- VITON(FKM FPM):VITON O-RING

ine yakanakisa kupisa kupisa, oxidation resistance, mafuta kuramba, corrosion resistance, uye atmospheric kuchembera kuramba, uye yakashandiswa zvakanyanya mundima dzakadai seaerospace, avhiyesheni, mota, petroleum, uye midziyo yemumba.Icho chinhu chakakosha chisingagoni kutsiviwa mune zvekucheka-kumucheto maindasitiri ekudzivirira kwenyika

- HNBR :HNBR O-RING

ine mafuta anodzivirira zvakanaka (kupikisa zvakanaka kumafuta emafuta, mafuta ekuzora, uye zvinonyungudutsa zvinonhuhwirira);Uye nekuda kwechimiro chayo chakanyanya kuzara, ine yakanaka yekupisa inodzivirira, yakanakisa kemikari kushora kusagadzikana (yakanaka kurwisa Freon, asidhi, uye alkali), yakanakisa ozone kuramba, uye yakakwirira compression zvachose deformation kuramba;Panguva imwecheteyo, hydrogenated nitrile rubber inewo hunhu hwakadai sesimba rakakwirira, kukwirira kubvarura kuramba, uye nekunaka kupfeka kuramba, zvichiita kuti ive imwe yeakanakisa marabha maererano nekuita kwakazara.

- CR(neoprene):CR O-RING

ine yakanaka yemuviri uye michina zvivakwa, mafuta kuramba, kupisa kupisa, murazvo wezuva, kuramba kwezuva, ozone resistance, acid uye alkali resistance, uye chemical reagent resistance.Izvo zvisingabatsiri ndezvishoma kutonhora kwekudzivirira uye kuchengetedza kugadzikana.Iyo ine yakakwira tensile simba, kurebesa, reversible crystallinity, uye yakanaka kunamatira.Kudzivirira kukwegura uye kupisa.Yakanakisa mafuta uye makemikari kuramba

FVMQ: FVMQ O-RING ine Yakanaka yemuviri uye michina zvivakwa uye kugadzikana kwemakemikari, inokwanisa kushandiswa kwenguva refu pa200.℃uye kushandiswa kwenguva pfupi pa250℃;Iyo brittleness point inotangira kubva -20℃kusvika -40℃;Yakanakisa yepakati kuramba, kugadzikana kwakanakisa kurwisa organic solvents, inorganic acids, uye oxidants, kunyanya yakanakisa asidhi kuramba;Iyo ine yakanakisa yemamiriro ekunze kuramba uye ozone kuramba.Mushure mekuratidzwa kumhepo yemhepo kwemakore akati wandei, maitiro ayo emuviri uye emuchina anochinja zvishoma, uye mhedzisiro yaro patupukanana zvakare yakagadzikana.

- FEPM(Aflas):FEPM O-RING

ine kugadzikana kwakanaka, kushomeka kwemakemikari, kunyanya kuramba kune yakanyanya kuwanda kweasidhi, alkali, uye yakasimba oxidizing ejenti yemhando dzakasiyana dzemafuta emotokari, mafuta ekuzora, mabhureki oiri, mineral oiri, uye silicone oiri, pamwe nekupokana kwakanyanya kumvura inodzvinyirira. mhute, mvura, uye kudzivirira magetsi.Iine kufema kwakadzika uye inogona kushandiswa patembiricha iri pakati -400 ne200 madhigirii celsius

- FFKM :FFKM O-RING

Iine elasticity uye kupisa uye kugadzikana kwemakemikari epolytetrafluoroethylene.Kushanda kwenguva yakareba tembiricha -39 ~ 288 madhigirii Celsius, kwenguva pfupi kusvika 315 madhigirii celsius, ichine imwe dhigirii yepurasitiki pazasi tembiricha yeembrittlement, yakaoma asi isina brittle, uye inogona kukotama.Yakagadzikana kune ese makemikari kunze kwekuzvimba mune fluorinated solvents.ndiyo Parizvino rabha inodhura zvakanyanya pasi rose.Brand:Kalrez

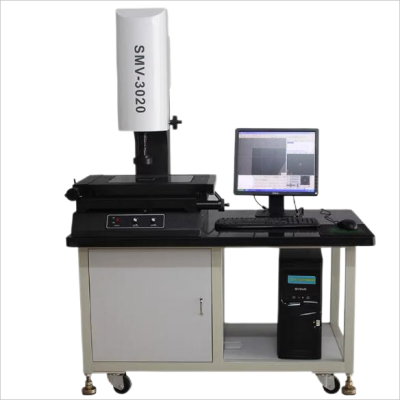

Yechishanu-rabha O-ring inotsanangurwa Nzira dzekuyera uye maturusi.

Zvishandiso zvekuyeresa zvakajairika vane:

1-High precision projector

Zviridzwa maitiro :Kuyera kusingabatanidzi kuyerwa, kuita kuti kuyerwa kusaonekwe uye kwakakodzera kuyera dzakatetepa-madziro uye dzakapfava zvikamu;Ine yakasimba yekusimudzira mufananidzo basa uye yakasimba diki kuyerwa kugona;Kukurumidza kuyerwa kumhanyisa kunonatsiridza kuyera kushanda zvakanaka; Iyo yakanyanya density yemasampling point inovimbisa kuvimbika kwakanyanya kwekuyera; Yakanakira clamping.

2-Electronic digital caliper

Zviridzwa maitiro :Chiyero chekuyera kureba chinoshandisa kuyema masisitimu akadai se capacitive uye magineti magidhi kuratidza zviyero zvemadhijitari.Iyo inowanzo shandiswa sarudzo ndeye 0.01mm, ine kukanganisa kunotenderwa kwe ± 0.03mm/150mm.Kune zvakare yakakwirira-chaiyo dhijitari calipers ine resolution ye0.005mm, ine kukanganisa kunotenderwa kwe ± 0.015mm/150mm.Kune zvakare yakawanda-chinangwa chedhijitari inoratidzira micrometer caliper ine resolution ye 0.001mm (inova patent yenyika yeAnyi yekuyeresa maturusi uye ivo chete vanogona kuigadzira), ine kukanganisa kunobvumidzwa kwe ± 0.005mm/50mm.Nekuda kweiyo intuitive uye yakajeka kuverenga, kuyerwa kwekuita kwakakwira.

3-π mutongi(PITAPE)

Zviridzwa maitiro :

1. Iyo π mutongi inoumbwa nesimbi yakatsetseka.Migumo yayo miviri yakateedzana yakanyorwa nevakuru uye vabatsiri vatongi.Iko kukosha kwekupedza kudzidza kwemutongi mukuru ndeye 0.5mm kana 1mm;Iwo mashoma ekupedza kudzidza maitiro emutongi anobatsira ari 0.02mm, 0.05mm, 0.01mm, 0.1mm, nezvimwe.

2. Paunenge uchishandiswa, putira π mutongi uchitenderedza workpiece uye shandisa nzira yekuverenga yevernier kuti uverenge zvakananga avhareji yepakati yechidimbu chakayerwa.

- Zvakanakira nezvayakaipira

(1).Kurongeka kwepamusoro: Sezvo dhayamita richiyerwa kuburikidza nedenderedzwa reiyo π mutongi, kukanganisa kwekumaka panguva yekugadzirwa kwemutongi kunogona kuderedzwa ne π nguva uye kuratidzwa mumhedzisiro yekuyera.Saka mu φ Muzviyero zvakakura zvedhayamita pamusoro pe500mm, kurongeka kwayo kwakakwira kupfuura iyo yevernier caliper.gara φ Mukana uyu unonyanya kuzivikanwa muzviyero zviri pamusoro pe1000mm.

(2).Pakuyera zvikamu zvesimbi ne π mutongi, hazvikanganisi nekupisa kwechikamu chebasa.Izvi zvinodaro nekuti iyo π mutongi mutete zvakanyanya, uye ichave iri imwe yakajairika nechidimbu chakaedzwa munguva pfupi pfupi panguva yekuyera.Pamusoro pezvo, iwo ekuwedzera kwemafuta ekuwedzera coefficients ari padyo, zvakanyanya kukunda pesvedzero yekushisa.

(3. Mukuyera kwemadhayamita makuru uye akawedzera, kushandiswa kwezvikamu zvekubatsira (patented magnetic bridges) inobvumira kushanda nyore nemunhu mumwe panguva.

(4).Kuyera zvikamu zvakatetepa-madziro hazvisi nyore kukonzera deformation yebasa rekushanda.(5).Zviri nyore kutakura uye kuchengeta (6).Mutengo wakaderera.

(7).Zvakaipa: Kutadza kuvhara kuverenga;Geometric deviations senge ovality haigone kuyerwa.

Yechitanhatu O-ring Kushandisa uye o-ring yekuisa.

1. Kushandiswa kweO-ring

O-mhete inoshandiswa zvakanyanya pamajoini eakasiyana hydraulic uye pneumatic components, cylinder surfaces, uye flange surface.Kune O-mhete dzinoshandiswa panguva yekufamba, apo kushanda kwekushanda kwakakura kudarika 9.8Mpa uye pasi pekumanikidzwa kweunidirectional, chindori chekuchengetedza chinofanira kuiswa kune rumwe rutivi rweO-ring munzira yekumanikidza;Kana ukaiswa pasi pekumanikidzwa kwebidirectional, isa rin'i inochengeta pamativi ese eO-ring.Kuti uderedze kukwenya, mhete dzekuchengetedza dzakaita seweji dzinogona kushandiswa zvakare.Kana iyo yekumanikidza mvura ikaiswa kubva kuruboshwe, yekurudyi inochengetedza mhete inosundirwa kumusoro, uye yeruboshwe inochengeta mhete haisangani neyakavharwa pamusoro, nokudaro kuderedza simba rekukwenya.Pakazere, kushandiswa kwemhete dzekuchengetedza kunowedzera simba rekukwesha remudziyo wekusunga, uye mhete dzekuchengetedza dzakaita wedge dzakakosha zvikuru mukudzikisa uku kukwesha simba.Kune yakagadziriswa O-mhete, rin'i yekuchengetedza inodiwa zvakare kana kumanikidza kwekushanda kuri kukuru kupfuura 32Mpa.

2. Kuisa oring

Kuiswa kwemhando yeO-rings kune zvakakosha pakuita kwavo chisimbiso uye hupenyu hwebasa.Matambudziko ekudonha anowanzo kukonzerwa nekusaisa zvakanaka.Panguva yekugadzika, hazvibvumidzwe kuve neO-ring scratched, kusarongeka, kana kumonyoroka.Pamberi pekusangana, chisimbiso groove uye chisimbiso chekuisa chisimbiso chepamusoro chinofanira kunyatsocheneswa;Panguva imwecheteyo, shandisa mafuta ekuzora pamusoro anoda kupfuura panguva yekusangana kweO-ring.Kudzivirira O-ring kuti irege kutemwa kana kukweshwa nemicheto yakapinza semakona akapinza neshinda panguva yekuisa, 15 º kusvika 30 º lead-in angle inofanira kusiiwa kumucheto kweshaft uye gomba kumagumo ekuiswa.Kana iyo O-ring inoda kupfuura neshinda yekunze, yakakosha-yakatetepa-yakakomberedzwa simbi inotungamira sleeve inofanira kushandiswa kuvhara kunze kweshinda;Kana iyo O-ring ichida kupfuura nepaburi remukati, iyo orifice inofanirwa kuchinjika kuita inoenderana diagonal chimiro kudzivirira kukwenya paO-ring.Kutsetseka kwekona yegorozi kunowanzo ari = 120 º~140 º

Iwe unogona kudzidza zvakawanda zvine hukama ruzivo kubva pano.Gare gare, isu tichasuma imwe ruzivo nezvezvisimbiso zvemafuta, hydraulic chisimbiso,kana zvimwecustomized rubber parts,zvakaita seKatsi mafuta chisimbiso, NBR mafuta chisimbiso, FKM mafuta chisimbiso,TC mafuta chisimbiso, TB mafuta chisimbiso TA mafuta chisimbiso, SC mafuta chisimbiso SB mafuta chisimbiso,piston chisimbiso,tsvimbo chisimbiso ,spring seal ,bonded seal, u cup seal, dust seal,Wiper seal,pfeka mhete ,back up ring ,tambo dzerabha, o-ring tambo,saka tinoda nguva yakawanda tichisuma ruzivo urwu kumunhu wese.Ndatenda nenguva yako!